Frequently Asked Questions

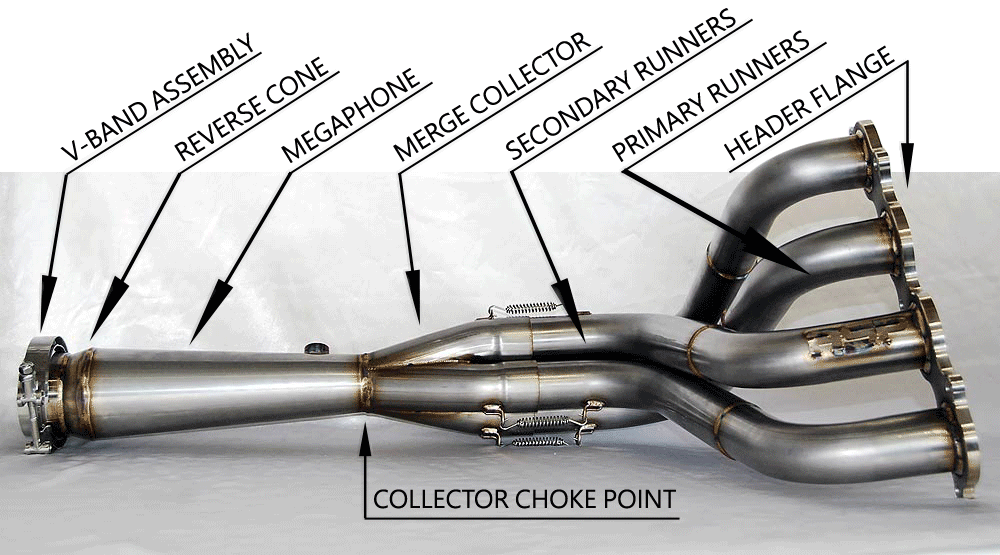

Header Terminology

|

What is the difference between header sizes?

|Standard Size Up to 300 hp +/-. As of of 2022, we are in the process of phasing out the Standard Size as a large majority of people are starting to purchase high flow CNC ported heads.

Big Tube Race Header Up to 400 hp +/-

Extreme Race Header 400 hp +. This size will be available for purchase online in 2023. If you need this size now, you can check with us as sales@aspheaders.com to see if we have the inventory available to build one for your chassis.

What information does ASP Headers need to build my header?

|Our custom headers are built to the client's engine specs on a first come first serve basis. Orders made at our online store will follow-up with a request form for additional engine specifications. We will contact you by email to confirm these engine specs. Stock engine specs can be listed as "stock". If you would like to send us your engine specs ahead of time, we ask for the following information:

Chassis:

Block:

Head: Ported? Flow #'s?

Intake Manifold or ITB's: Ported? Flow #'s? Port Matched? Size?

Bore/Stroke:

Top RPM: (At what RPM will the vehicle be commonly used?)

Compression Ratio:

Cams:

Fuel:

Vehicle Use: drag? road race?

Supercharged: y|n PSI?

Exhaust Size:

How will the information I provide be used?

|First we will confirm whether the header will be standard or big tube based on the estimated final horsepower output.

We will then determine the overall length of the header.

And finally, what length the primary and secondary runners should be.

How the vehicle will be used is a big determining factor, because it tells us how you want the power band to react. We want to effectively design the header to utilize the horse power to torque ratio where it will be used most often.

Example 1: Road racing requires a high level of hp at mid-range (6000-8000 RPM for K series).

Example 2: Drag racing requires a higher level of hp at the top end (8000-11000 RPMS for K series). The vehicle is never being used at a lower RPM, therefore you sacrifice power on the bottom end, but gain on the top end.

Consider the pros and cons of each, but remember that a good tuner can manipulate the cam timing to some degree by adjusting the power band as well.

How long will it take to have my header made?

|Our headers are built on a first come first serve bases, turn around time varies depending on how many builds are active prior to your order. We do not carry off the shelf headers. All headers are fabricated here in the US. We try to keep turn around time to no more the than 2 to 3 weeks. Consider the busiest time of the year is May through September.

Average Turn Around Time: October - December: 2 days to 2 weeks

Average Turn Around Time: February - April: 2 days to 3 weeks

Average Turn Around Time: May - September: 2 weeks to 5 weeks

What are the benefits to having a megaphone/reverse cone?

|The megaphone allows the gases to expand as they cool. The reverse cone increases the velocity of the exhaust gases, acting like a finger over a hose nozzle. When used with a full exhaust system, this improves mid-range. When running open header it broadens peak power.

All options using the megaphone reverse cone will include a 3" v-band assembly. One side will will be welded to the header, the other side will need to be welded to the exhaust locally. The clamp will lock the two sides together. This option will require an o2 sensor extension.

How would a custom header allow my engine to perform better?

|A Header eliminates back pressure that robs power to the motor. With our header's each cylinder gets its own equal length runner. This guarantees that at each pulse, exhaust gases will arrive through the collector spaced out. A header you might purchase off the shelf likely comes with four individual runners at a single size diameter. In comparison, all of our custom headers (not budget headers) are designed with 4 equal length runners of a specific diameter, then stepped to a secondary set of 4 equal length runners at a larger diameter. This creates a suction.

8th Gen Honda Civic - Will the K24 header also fit the K20 engine block?

|No, it will not fit unless you remove the front sway bar. It will clear the engine block because the deck height on the K24 is taller than the K20 block.

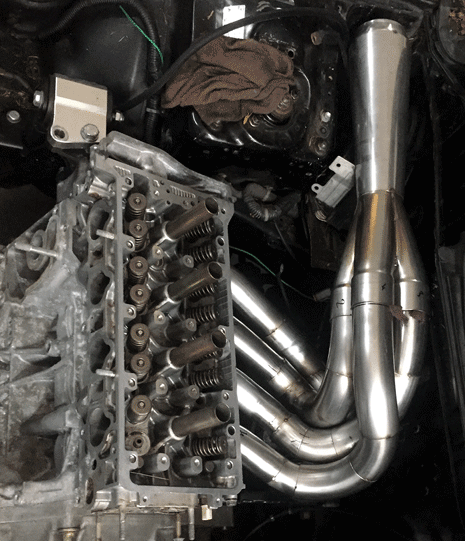

2008 Civic Si - I am getting ready to swap to a k24. Will your custom header clear my firewall?

|Yes, because we'll build the header specific to the engine block. We take the deck height difference into consideration.

Do the headers come with gaskets, bolts, and nuts?

|No. All stock OEM flange bolts and gaskets will match with the headers. When choosing the v-band assembly option, a matching v-band portion with clamp will be included.

Will the TSX standard 3 bolt flange bolt up to the stock cat?

|Yes

Does ASP Headers ship internationally?

|Yes, we ship internationally. Please request a shipping to sales@aspheaders.com. Include your full address and what item you are considering purchasing.

Do I qualify for a discount if I own a performance shop?

|As of January 1st, 2021, our dealer rewards plan has been updated. View Dealer Qualifications. Those of us at Advanced Street Performance LLC would like to thank our dealers and our clients who have helped prove the quality and performance of our headers.

What are my payment options?

|Orders purchase through online web site will require the header to be paid in full.

Place a deposit of $500 to get a build put on the build list. Contact us at sales@aspheaders.com to have a request sent to you. The remaining balance will be requested once the header is complete.

Headers are built on a first come first serve order. A deposit will put your build in line.

The Fabrication Process - Get What You Pay For

Header Terminology

|

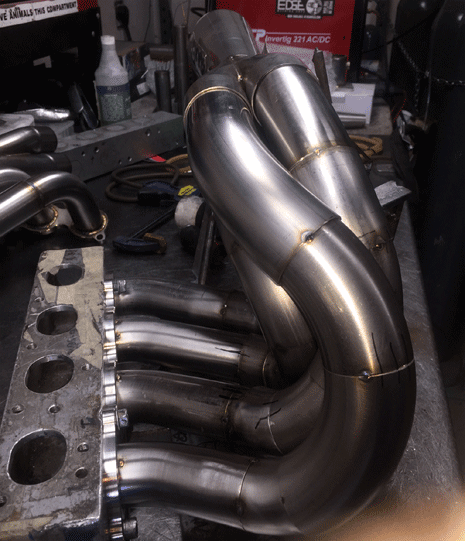

The process of building a header from start to finish.

|Whether or not we decide to make a new header design is based on how often we hear from people. Making one really good header requires a lot of time and money.

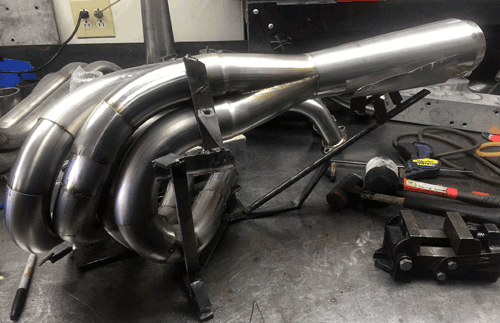

PHASE 1 - Fabrication

|

Fabricating the initial header design can be relentless. It's a puzzle that requires foreseeing how each runner will align with the others. The overall length of each runner and it's individual diameters need to be the same length for exhaust gases to expand in synchronization.

PHASE 2 - Fixture Design

|

Our initial header design is fabricated on the chassis, but we don't always have the vehicle for long. By making a fixture we not only save time, we are able to ensure future builds are made within the correct boundaries. It leaves less room for error if there is more than one person working on the header.

PHASE 3 - Quality

|

We take the time to clean the material prior to welding. This is crucial in preventing microscopic air pockets and contaminants in the welds. Dirty welds can eventually lead to cracking. Some manufactures will hide these flaws by grinding down the welds then polishing them.

All of our headers are back purged. This is a process where any openings are plugged, then filled with argon gas throughout the welding process. This ensures welds successfully penetrate throughout the interior, not just the exterior. This costs more, but the result is a much stronger weld that will last a lifetime.

Our bends are made specific to each headers design. This cuts back on labor cost since it makes for a faster build time. Custom bends also confirm continuity and provide a cleaner look having less pie cuts.

We use US grade 304 stainless steel. 304 stainless steel should not have more than .08% carbon content. Carbon content is magnetic and corrosive. It's important to note that some countries self regulate the quality of material they sell. If the material is cheap, it's likely to have more carbon content then the grade suggests it has. You can test this by running an earth magnet along it's smooth surface. 304 stainless is not magnetic. If it shows magnetism, this means there are contaminants in the material that will eventually cause rust.

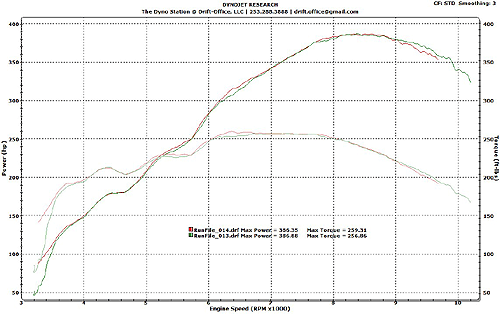

PHASE 4 - Performance R & D

|

Tuning the engine with the header not only makes sure the engine stays in good running condition, but confirms horsepower and torque are adjusted to the appropriate RPM.

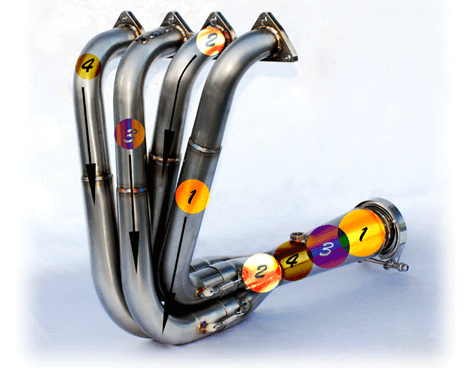

A good header uses the momentum of the surrounding exhaust gases to its benefit. To do this, the header should have equal length runners and the appropriate diameter to the engine specs.

Note the firing order on a K-Series engine is 1-3-4-2. These gas pulses should stack one after the other much like dominos. If the runner lengths are off, the gas pulses will be forced to arrive at the same time, pushing the pulses out of rhythm resulting in a loss of horsepower and torque.

On an ASP Header, we step the runners from a smaller size to larger size. These individual runners also need to be equal length. We step them to increase scavenging. This is where low pressure behind the exhaust gases create a siphoning effect. Like with water, you can see that if the diameter of the tube is too large you will loose the back pressure needed to scavenge the gases. Or if you have a lot of back pressure, then you need a large tube to support the flow.

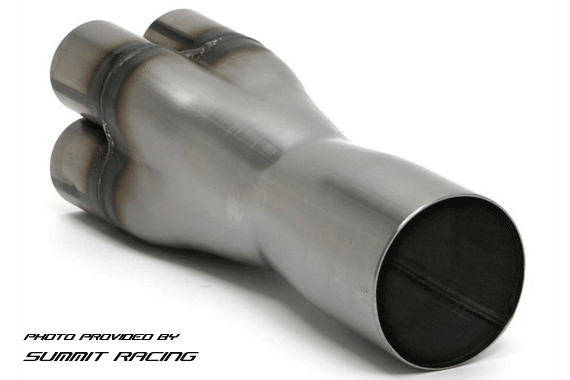

Our true merge collectors are made right here in the USA, hand engineered to for superior flow and velocity. Besides labor, the merge collector is the most expensive piece on the header. But lets compare the cheaper, less effective collector.

This is a formed collector, not to be mistaken with a true merge collector. It lacks a spike in the middle of the four runners and the squeezed form is slipped over the top to be welded on. A spike can be purchased separately to fill in the center or not.

► One of the most often overlooked strategies to gaining HP is the headers overall length. Therefore, the exhaust should be customized to match the header, not the other way around. For convenience and compatibility for all, most manufactures end the header at specific stock location. By using the megaphone, this ensures the user will match the exhaust to the header and gives us the opportunely to make a longer header if the engine specs call for it.

► When exhaust gases cool down, they lose momentum. Using the megaphone with reverse cone, this pools the cooler gases together and acts like a finger over a hose nozzle, speeding up and shooting them out. The result is a smoother transition at a higher level HP to TQ ratio throughout the RPM band.

PHASE 5 - World Wide

|

Finally, we have a base design. From here, we can customize to individual engine specs. We can change the diameter of tubing, we can change the overall length, we can have the header step from one, two, or three different sizes, and we can change the length of those individual sizes. All of these strategies affect how the header will perform.

Since 2007, ASP Headers, LLC has been matching all sorts of K series variations to custom headers. As you can see we put a lot of focus on K-series engines and our experience will be your gain.